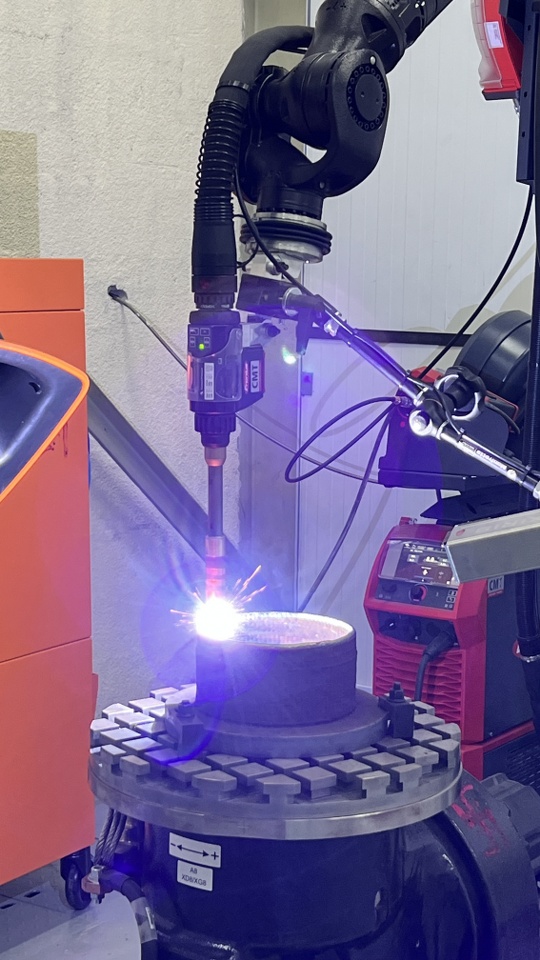

At the core of JOME's capabilities is the sophisticated Wire Arc Additive Manufacturing (WAAM) process. Unlike traditional subtractive manufacturing (like machining, which removes material), WAAM builds parts layer by layer by melting metal wire using an electric arc. This allows the facility to tackle projects that were previously impossible or cost-prohibitive.

Massive Production Capability: JOME's facility is engineered to produce components with extraordinary dimensions, often reaching up to two meters in size. This capability immediately opens doors for high-demand sectors like marine, oil and gas, and heavy engineering that require large, robust parts.

High Deposition Rates: Crucially: WAAM offers high deposition rates, meaning metal material is added quickly. This drastically reduces the time required for prototype development and the production lead times for final components, allowing clients to get their products to market or back into operation much faster.

JOME’s investment in WAAM technology is driven by its inherent advantages in efficiency and design flexibility:

Minimized Material Waste: By building components only where material is needed (near-net-shape manufacturing), WAAM significantly minimizes material waste compared to traditional machining processes, which can generate substantial scrap. This makes the process more cost-effective and environmentally sustainable.

Production of Complex Geometries: The layer-by-layer nature of AM allows engineers to create complex internal features, lattices, and consolidated parts that are impossible to achieve using conventional methods. This expansion of design possibilities leads to lighter, stronger, and more functionally advanced components, particularly vital for aerospace and high-stress applications.

This significant investment in next-generation manufacturing technology reflects JOME Engineering’s profound and long-term commitment to innovation and engineering advancement in the region. By providing local access to world-class large-scale metal 3D printing, JOME is actively supporting the UAE’s industrial diversification goals, ensuring that critical sectors have a reliable, efficient, and technologically advanced source for their most demanding metal component needs. JOME is not just adopting technology; it is setting the standard for the future of metal fabrication.